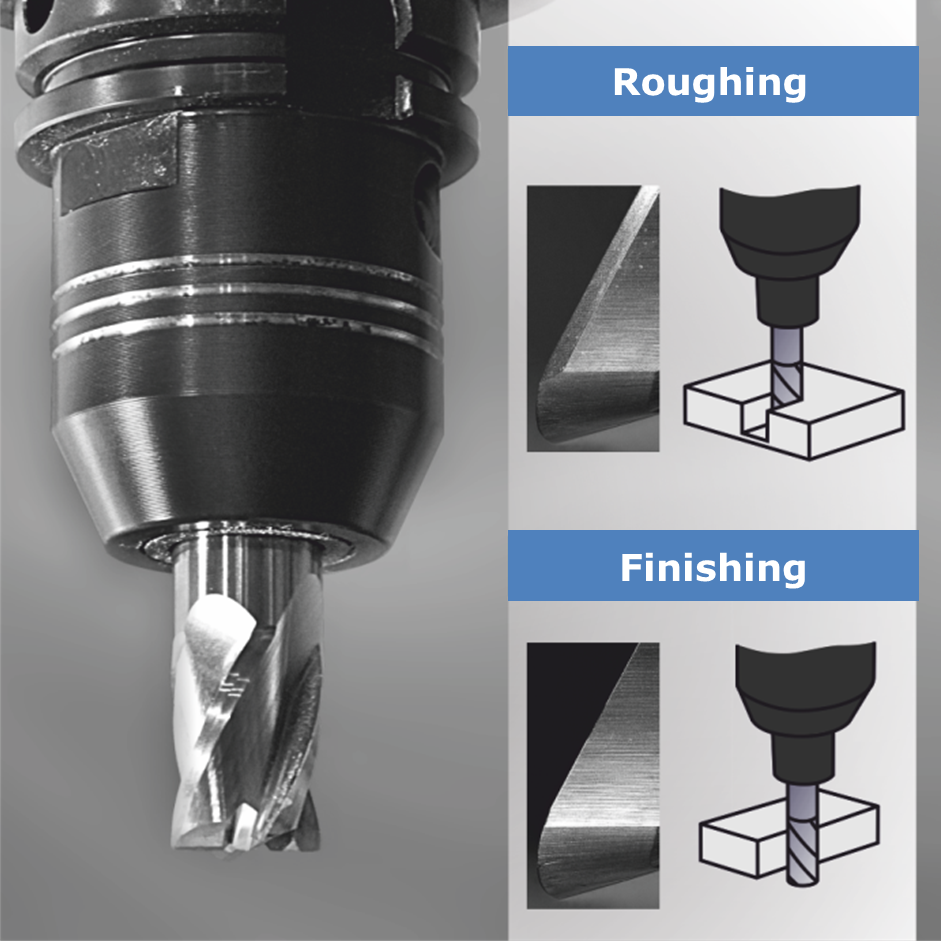

High performance milling tool for roughing and finishing

// Mechanical Engineering // Production Technology

Ref-Nr: 15498

Abstract

The tool has two different cutting edges: chamfered cutting edges are used to prevent chattering, while sharp cutting edges generate the final surface due to their greater distance from the tool axis. Advantages are: Roughing and finishing operations possible with a single tool, counteracting burr formation and high chip removal rates.background

During high-performance machining, chatter vibrations can occur that were previously prevented/reduced by a free surface chamfer on the milling tool. If a free-form chamfer is used, the highest surface quality can only be achieved with difficulty.

Innovation / Solution

The new milling tool can reduce the formation of burrs and enable the highest chip removal rates without chatter with a high surface quality. According to the invention, one pair of cutting edges has a sharp cutting edge, while the other pair of cutting edges has a supporting chamfer. The chamfered cutting edges are reset by a certain amount from the tool radius. The chamfered cutting edges serve to prevent rattling, while the sharp cutting edges generate the final surface due to their greater distance to the tool axis. The new tool concept increases process stability, improves surface quality and reduces burr formation. By varying the feed rate and cutting speed, the new tool can perform both roughing and finishing operations.Benefits

Roughing and finishing operations possible with a single tool

Counteracting burr formation

High metal removal rates

You can close this window. You can find your search results in the previous window