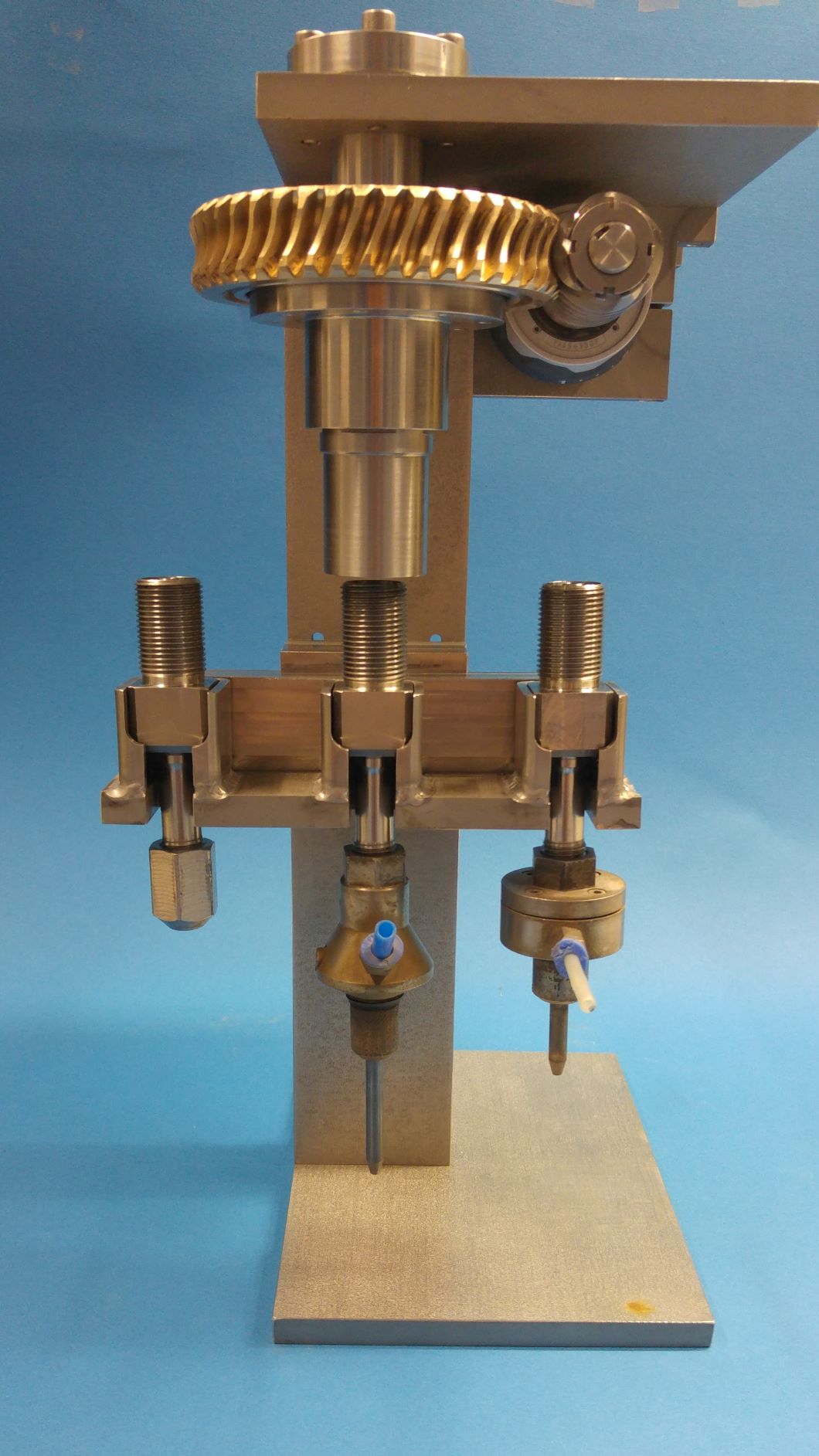

Cutting head turret

// Mechanical Engineering

Ref-Nr: 16429

Abstract

The invention relates to a cutting head replacement system for water jet cutting. For the first time ever, with this new technology an automated cutting head change is possible.background

Currently, the cutting head is changed manually – a change takes about three minutes. Until now, there is no automated change system for cutting heads in waterjet technology.

Innovation / Solution

The task of the new technology is to connect the collimation tube (stationary) with the cutting head. The collimating tube should have an external thread on which a nut element, which includes two different internal threads, can move up and down. The nut element can be driven by a motor via a worm drive. For the first time, this technology en-ables an automated cutting head change and guides the waterjet technology towards full automation.Benefits

Safe connection of the cutting head with the pressure system

For the first time, automation of the cutting head chance possible

Cost advantages by automation

fields of application

The field of application of the new technology is water jet cutting. It includes a device for connecting cutting heads (pure and injection water jet cutting) to the printing system - the connection process can be automated.You can close this window. You can find your search results in the previous window