From stubble to cultivated field in one pass: Innovative plow system with parallel-mounted plow bodies makes it possible

Abstract

The technology presented is an innovative parallel plow system designed for agricultural use, capable of significantly increasing the efficiency of soil cultivation.background

Until now, full-turn plows and single-sided plows have commonly been used. In these models, the plowshares are arranged in a staggered, sequential manner, resulting in a long, angled structure.

The disadvantages of such plows include complicated turning maneuvers and wedge-shaped sections left at the field headland. Due to their length, these plows cannot be combined with other implements – such as a following packer roller or a seed drill. The tractor’s operation can therefore be used exclusively for plowing.

Increasing the efficiency of current plows has generally meant scaling up, but this approach is reaching its limits. The use of parallel plowshares is difficult with current technologies, as it frequently leads to blockages in the space between the plowshares.

Innovation / Solution

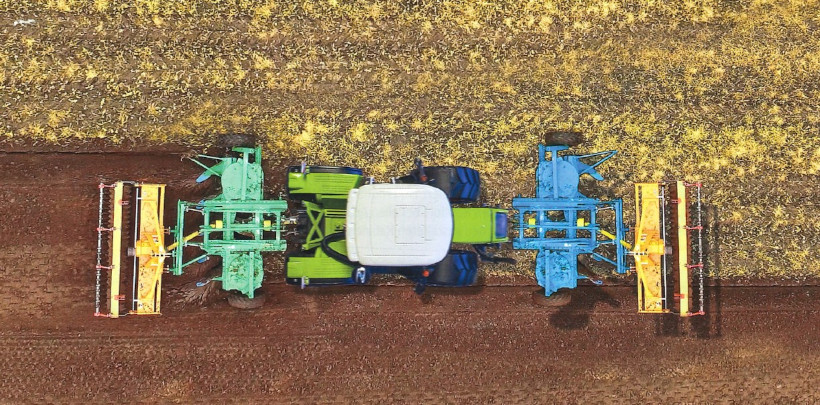

The core of the invention consists of the first and currently only feasible implementation of parallel-arranged of plowshares (see Fig. 1). This reduces the overall length of the plow, enables straight passes at the headland, and allows a combination with other soil cultivation equipment in a single operation. Two main construction principles make this possible: first, relocating the guiding mechanics to the outer section, and second, omitting the coulter beam (the upwards extension of the mouldboard). A skim coulter can be mounted in front of each plowshare if needed. Behind the parallel plow, a rotary harrow as well as a packer roller and even a following seed bar can be attached simultaneously. This is made possible only through the compact design of the parallel plow. This configuration enables complete soil cultivation – “from stubble field to fully prepared field” – can be carried out in just one pass. With this system, plowing can begin directly at the field edge, eliminating the need for a headland. If two systems are available, one can be mounted at the front and the other at the rear of the tractor (e.g. Claas XERION). As a result, turning maneuvers can be completely eliminated, leading to further increases in efficiency and making the system particularly suitable for autonomous tractors. A prototype of the invention has been built and successfully tested. Compared with conventional systems, the driving speed of the tractor in the field can be increased from 6 km/h to 13–15 km/h – with the soil flow remaining consistent. Overall, this results in significant economic benefits, particularly by saving time and fuel.Benefits

You can close this window. You can find your search results in the previous window