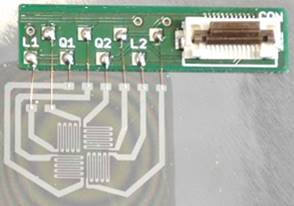

Manufacturing method for bridge circuits

// Electronics and Electrotechnology // Material Technology // Measuring and Control Technology // Sensors and Measuring Instruments

Ref-Nr: 16551

Abstract

The invention concerns a procedure for the defined adjustment of sensor parameters. The deposition of the sensors takes place e.g. by means of cathode sputtering or chemical gas phase deposition e.g. directly on the technical surface of components. With this innovative process, the sensors can be specifically adjusted to a predefined characteristic value or, for example, directly calibrated during production.background

High demands are made on sensors with regard to homogeneity and manufacturing quality. In the field of temperature or strain measurement sensors, for example, compliance with defined resistance values is of great interest. This applies in particular to the interconnection of sensors in bridge circuits.

Innovation / Solution

Previously, sensors were set to the desired target value after the actual manufacturing process, a costly and time-consuming process. The technology of the invention includes that individual sensors or bridge circuits can be set to the desired final value during production. This is achieved by permanently monitoring the desired target value in combination with a trimming device during the manufacturing process.Benefits

High-precision manufacture of a complete bridge circuit with continuous quality control

Transferable to other manufacturing processes

Novel possibilities of sensor production, e.g. of completely trimmed and directly deposited sensor technology on technical surfaces

Retrofitting of existing production systems possible

fields of application

Sensor production, manufacture of bridge circuitsYou can close this window. You can find your search results in the previous window