Bestimmung des Auslastungsgrades elektrischer Betriebsmittel unter Berücksichtigung der aktuellen Temperatur des Betriebsmittels, Strombelastung und Umgebungsbedingungen

// Energie- und Energiespeichertechnik // Energietechnik // Energieübertragung // Sensorik und Messgeräte

Ref-Nr: 16635

Einleitung / Abstract

Die Erfindung sieht ein neues Verfahren vor, welches z.B. den Betriebszustand in einer elektrischen Schaltanlage, eines elektrischen Betriebsmittels eindeutiger als in bisherigen Verfahren ermittelt und überwacht. Dabei wird ein Temperatur-Monitoring eingesetzt, das sich u.a. auf Temperaturmessung, Strom-Istwert-Bestimmung, Messort und Erwärmungszeitkonstanten stütztHintergrund

Derzeitig wird Temperaturmesstechnik innerhalb von Schaltanlagen oder elektrischen Betriebsmitteln eingesetzt. Ausgehend von den Temperaturmessstellen kann eine mögliche Temperaturverteilung innerhalb der Schaltanlage oder des Betriebsmittels simuliert werden.

Problemstellung

Mit den bisherigen Verfahren kann die Ursache eines Temperaturanstiegs nicht hinreichend genau festgestellt werden, da sich z.B. verschiedene Effekte überlagern können. Außerdem wird die Kombination aus mehreren physikalischen Messgrößen wie der fließende Strom und die Umgebungstemperatur der Schaltanlagen nicht zur weiteren Analyse in Relation zueinander genutzt und in der Regel auch nicht erfasst.Lösung

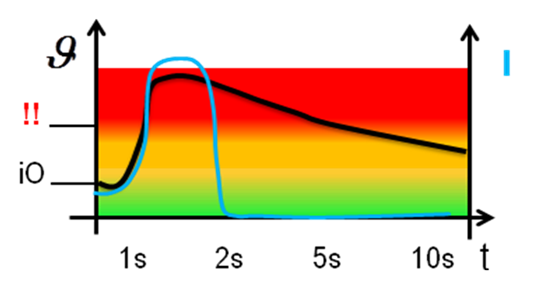

Die Erfindung beschreibt ein Verfahren, dass neben der Temperaturmessung weitere wichtige Prozessparameter (z.B. Strom, Umgebungstemperatur, Schaltzustand, etc.) erfasst, den zeitlichen Verlauf der Parameter aufzeichnet und miteinander in Verbindung bringt. Die Daten werden durch eine entsprechende Rechentechnik in einer Datenbank hinterlegt und auf charakteristische Muster untersucht. In Abhängigkeit des ermittelten Temperaturverlaufs und der aufgenommenen Prozessparameter ist es möglich, auf die Ursache der Erwärmung zu schließen. Im Folgenden sind mögliche Szenarien aufgelistet, die durch das Verfahren nachvollzogen und eindeutig identifiziert werden können: • Kurzschlussfall, • Auftreten von Wirbelströmen, • Anstieg der Umgebungstemperatur, • Aussagen über den räumlichen Temperaturverlauf, • Änderung der Strömungsverhältnisse der Kühlung, • Veränderung der Umgebungsparameter durch Umbauten, • Änderung des Schaltzustands des Betriebsmittels.Vorteile

Mit den detaillierten Messdaten können wichtige Erkenntnisse für die Weiterentwicklung von Betriebsmitteln und Prozessen gewonnen werden.

Mit Hilfe von einfacher Rechentechnik gelingt eine zustandsorientierte Wartung des Betriebsmittels.

Der Auslastungsgrad des Betriebsmittels kann optimiert werden.

Veränderungen am Betriebsmittel können früh erkannt werden.

Es wird keine zusätzliche Einrichtung (Batterie, Stromversorgung) benötigt, da für die Eigenversorgung der Messtechnik Energie gewonnen wird.

Anwendungsbereiche

Zunächst ist das Verfahren nur für den Einsatz in elektrischen Energieverteilanlagen vorgesehen. Jedoch lässt sich die Anwendung auf alle Bereiche erweitern, bei denen Prozessparameter (z.B. Temperatur, Strom, Stoffflüsse) erfasst und ausgewertet werden sollen. Darüber hinaus kann der Temperatursensor gegen andere Sensoren ausgetauscht werden, welches weitere Applikationen ermöglichen würde.Sie können dieses Fenster schließen. Ihre Suchergebnisse finden Sie in dem vorherigen Fenster