SYSTEM FOR AUTOMATED CLEANING OF SOLAR POWER PLANT USING DRONES AND ROBOTS

// Electronics and Electrotechnology // Power Engineering // Solar Technology / Photovoltaics

Ref-Nr: 17109

Abstract

The method according to the invention is intended to be used to significantly increase the efficiency of solar power plants through regular and effective automated cleaning with low investment and operating costs, thereby increasing the energy yield. At its core, a solar power plant consists of solar modules that are permanently installed on mechanical tables. Soiling of the modules can significantly reduce the yield, especially in sandy areas.background

There are various possibilities for cleaning solar modules, which have various disadvantages:

1. self-cleaning by lotus effect

Disadvantage: works only at higher installation angles and regular rainfall

2. manual cleaning

Disadvantage: very high operating costs

3. cleaning systems permanently installed on solar tables

Disadvantages: very high investment costs, maintenance-intensive

4. manually transportable robots

Disadvantage: investment costs

5. Drones with brush

Disadvantages: low cleaning efficiency, high time required due to frequent loading necessary.

Innovation / Solution

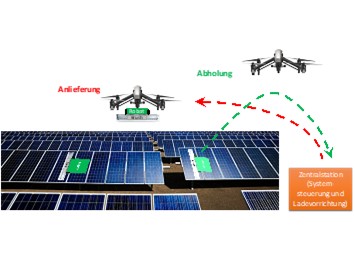

The invention consists of three main components: Mobile robots for cleaning, drones for transporting the robots, charging stations for charging the drones and robots. The robots, which are optimized for the cleaning task, are transported by the drones to their destination, where they automatically carry out the cleaning process. The locations and loading statuses are regularly exchanged by means of position determination and prior referencing. Once cleaning is complete, the robots are transported by the drones to the next table or for reloading. Precise positioning and a sensor system enable the robots to clean the entire table surface effectively. Thanks to an automated process, the drones are able to localize, automatically couple/uncouple and transport the robots. The drones are loaded as required between transport operations. System control using artificial intelligence can optimize the flight path and runtime of the cleaning process by taking into account loading statuses, cleaning areas, weather conditions, dirt and the extent of the area.Benefits

High plant efficiency and high yield due to continuously low contamination levels

Low material usage of cleaning equipment

Low use of personnel

Later or temporary extensions (e.g. seasonal) possible

fields of application

Automated cleaning system of solar power plants.You can close this window. You can find your search results in the previous window