Valve for water abrasive suspension jet cutting

Abstract

The technology according to the invention relates to a valve for water abrasive suspension jet cutting for interrupting and releasing a water abrasive suspension jet.background

In waterjet cutting, a distinction is made between pure waterjet cutting and abrasive waterjet cutting. Pure waterjet cutting is only suitable for cutting soft materials, which is why abrasive waterjet cutting is mostly used industrially. It is suitable for cutting almost all materials and is divided into injector jet cutting and suspension jet cutting. So far, only injector jet cutting has been used for industrial part production, in which the abrasive is added only after the jet has been generated. Air also enters the jet together with the abrasive. In suspension jet cutting, on the other hand, the abrasive is premixed with the water, compressed together to high pressure and accelerated in the cutting nozzle. Therefore, the suspension jet does not contain any air at all in the cutting jet, which potentially increases its cutting performance and accuracy. However, due to the abrasive contained in the water, it is not possible to interrupt a suspension jet using a switching valve. The particles in the suspension prevent valve closure. Therefore, there is currently no solution for interrupting and re-releasing a water abrasive suspension jet. To interrupt the cutting jet, the entire high-pressure generation is currently switched off.

Innovation / Solution

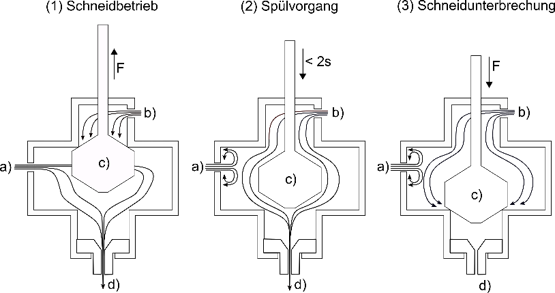

By interrupting the water abrasive suspension jet at the cutting head, a fast switching process is made possible in contrast to interrupting the cutting jet by switching off the entire system. This enables cutting of internal contours and handling of water abrasive suspension jet systems comparable to that of standard industrial systems based on water abrasive injector jet technology. A suspension switching valve can therefore be used to combine the application possibilities of an injector blasting system with the high efficiency of a suspension blasting system. For this purpose, a needle valve with a cylindrical shaft is used in conjunction with a plain bearing bush with helical flow channels.Benefits

fields of application

The field of application of the invention is waterjet cutting.You can close this window. You can find your search results in the previous window