Method for the morphological characterization of nonwovens by polarimetry

Abstract

The inventive technology concerns the characterization of electro-spun nonwovens in the fields of implantology and medical technology (tissue engineering).background

The artificial production of biological tissue by the directed cultivation of cells in order to replace or regenerate diseased tissue in a patient is summarised under the term “tissue engineering”. Before culture, the structural scaffold is combined with the removed vital material to form a 3D cell culture. The focus is on polymers that are processed into nonwovens by electrospinning. Their fibers have diameters ranging from several hundred nanometers to a few micrometers. For the replication of complex tissue structures (e.g. tendon-bone transition), graded nonwovens with a combination of aligned and unaligned fibers are important. The design and manufacturing parameters of the nonwovens determine the mechanical properties of the nonwovens and the strength of the implants.

Motivation

For the morphological characterization of the fibers of (graded) nonwovens, methods based on scanning electron microscopy (SEM) and RAMAN spectroscopy are currently used. The measurements are time-consuming, cost-intensive and lead to an irreversible impairment of the samples. At the same time, only very small areas can be measured per measurement.Innovation / Solution

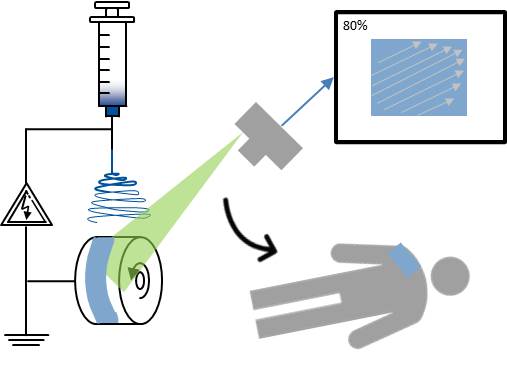

The inventive technology comprises a non-destructive measuring method and a measuring system for rapid characterization of the functional and qualitative characteristics of the fibers, such as the total orientation of the fibers of electro-spun nonwovens, using the Mueller matrix. The measuring principle is based on polarimetry both in reflection and in transmission and allows a measurement in a few seconds, without the fleece being prepared beforehand or being impaired as a result of the measurement. The measuring principle does without mechanically moving components and uses liquid crystal technology. A compact, portable instrument design is possible, which makes its use in the operating room in the context of a transplantation conceivable.Benefits

fields of application

The invention can be applied, for example, in the manufacture of implants and in clinical applications (implantation procedures).You can close this window. You can find your search results in the previous window