Carbon fibers with high electrical conductivity

// Material Technology

Ref-Nr: 16261

Abstract

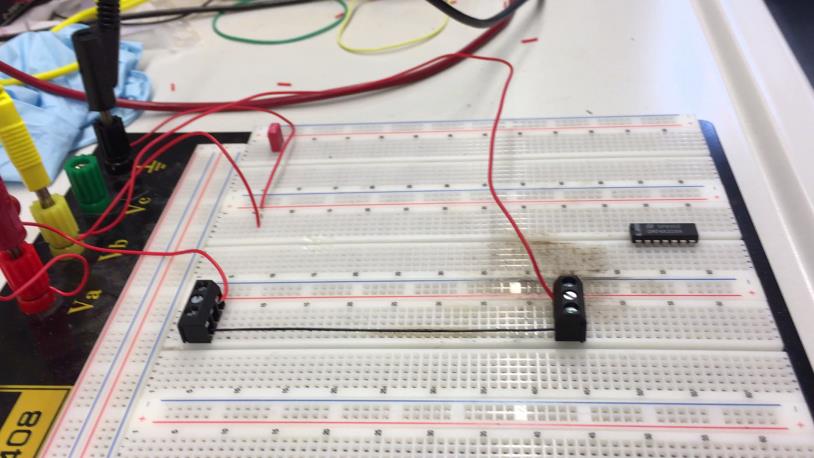

The invention concerns the manufacture of electrical conductors as "lightweight construction". An experimental setup is set up in the laboratory. Fig. 1 shows a test setup for measuring the electrical conductivity of the fibers.background

Carbon fibres in various technical areas are specially synthesised, and their design is usually based on their mechanical properties. A high proportion of graphite already ensures electrical conductivity, which is even lower than that of metallic conductors such as copper or aluminium.

Innovation / Solution

Electrically conductive carbon-based fibers (in the submicrometer range) are produced in four steps: electrospinning, cyclisation, denitrification and carbonisation. Cyclization takes place under several hours of tensile stress, so that the fibers become thinner and longer. Molecular ordering processes occur. In the last two steps (high-temperature treatments), the atmosphere (vacuum or inert gas) suppresses oxide formation.Benefits

higher conductivity than metals

low density (lightweight construction)

in high-frequency technology: high charge carrier mobility and suppression of the skin effect due to the high specific surface area

You can close this window. You can find your search results in the previous window