Injection 3D printing

// Construction Technology // Machine and Plant Construction // Mechanical Engineering // Production Technology

Ref-Nr: 16776

Abstract

The objektive of this technology is to improve the additive manufacturing of concrete components in order that geometrically complex and individual components can be produce efficienty.background

Additive manufacturing strategies are transferred to large-scale building components made of concreate. Additive manufactoring methods heretofore known in the state of the art are extruding concrete strands and particle bed printing.

Innovation / Solution

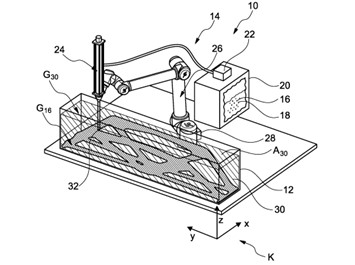

The technology according to the invention is fundamentally based on the principle of additive manufacturing in a liquid. This method is intended to solve both the problem of spatial shaping, the weakened contact surface between the horizontal layers, as well as the integration of the reinforcement in tensile loaded areas of concrete components. In "Injection 3D Concrete Printing", a liquid is firstly used, which among others has the same density as concrete, placed in a container. The properties of this liquid are adjusted so that it acts as a support liquid for the still uncured concrete mass and thus as a formative formwork. The concrete is injected into the liquid-filled container and then "hang" in the liquid it is cured.Benefits

Free shaping of concrete components by means of additive manufacturing technology

Efficient production of stress path optimized concrete components

New possibilities for integrating reinforcements and setting locally differentiated material properties in concrete components

fields of application

The field of application of the new technology is the production of concrete components using additive processes.You can close this window. You can find your search results in the previous window