Method for the oxygen-free production of a component

// Measuring and Control Technology // Mechanical Engineering // Production Technology

Ref-Nr: 16323

Abstract

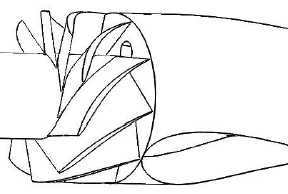

The invention relates to a machining method for oxygen-free production and the devices necessary for this purpose. In this way, in particular, the oxidation processes responsible for tribooxidations can be prevented and the wear of the tools can be reduced. FIG. 1 shows a drill which guides a protective gas through a compressor through channels provided for this purpose to the engaging tool area.background

Manufacturing processes are usually carried out in natural air atmosphere, whereby a permanent oxidation of the surfaces of the workpiece and tool takes place.

Motivation

Even with the known technologies for reducing the oxidation by conventional inert gas atmospheres or by generating a high-grade technical vacuum, oxide layers occur.Innovation / Solution

According to the invention, the surroundings are exposed to the protective gas Si4H10 before the beginning of the cutting process. During the machining process, the silane concentration of the shielding gas is then changed, which is to prevent the reduction in tool life caused by tribooxidation. In order to obtain optimal chemical reactivity, the cutting parameters (feed and cutting speed), the silane concentration and the protective gas concentration should be set as a function of each other. For local admission of the protective gas, gas inlet channels can be provided inside the tool.Benefits

Reduction of wear progress on the cutting edges

Increased performance and tool life

Recycling possibility of chip

fields of application

Fields of application of the invention are in manufacturing processes of the metalworking industry.You can close this window. You can find your search results in the previous window